Advanced Technology of Gear and Worm Rolling Forming Engineering

Seenpin has long been engaged in the research and production of ultra precision machining and rolling machining of gears and worms. Accumulated rich experience in processing technology, it has a good foundation for the mass production of planetary roller lead screw & electric cylinder, Modular Intelligent joint series products, and can provide high-quality, high-performance, high-precision and reliable parts of planetary roller lead screw and modular joint.

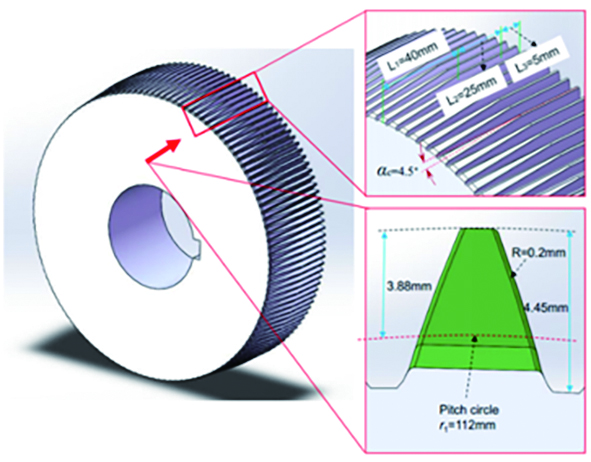

Technical features: Rolling technology has high production efficiency, small size dispersion, high material utilization rate, good surface quality of formed gears, threads, splines, etc., high mechanical strength, corrosion resistance, wear resistance, and excellent comprehensive performance, But the gear pressure angle must be greater than25°, which can replace some hobbing gears.

Technical features: Rolling technology has high production efficiency, small size dispersion, high material utilization rate, good surface quality of formed gears, threads, splines, etc., high mechanical strength, corrosion resistance, wear resistance, and excellent comprehensive performance, But the gear pressure angle must be greater than25°, which can replace some hobbing gears.